Form

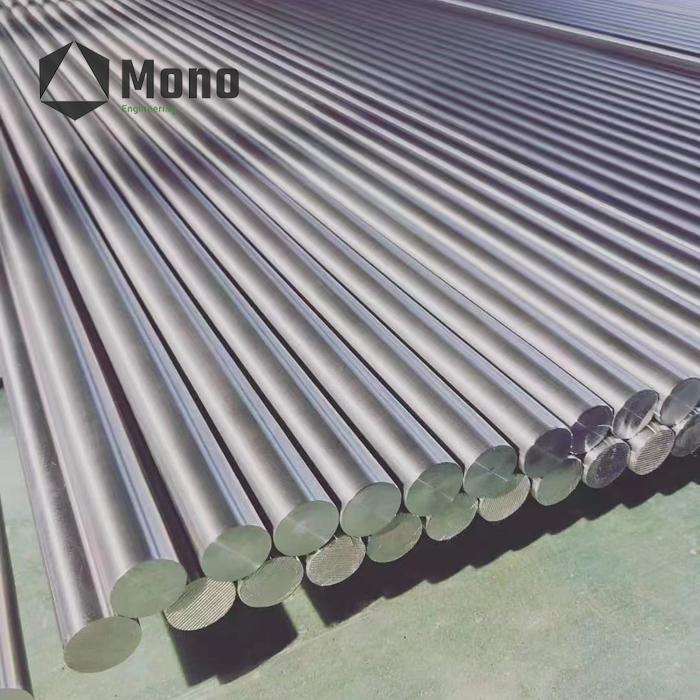

This specification covers an Aerospace using Alpha-beta 6Al-4V Titanium alloy Bars,Wire, Forging, Rings and Drawn shapes (Solution Heat Treatment and Aged ) in 4.000 inches (101.60 mm) and under in nominal diameter or least distance between parallel sides and of stock for forging and flash welded rings.

Application

These products have been used typically for parts which are machined after solution heat treatment and aging and are suitable for parts requiring high strength-to-weight ratios up to moderately elevated temperatures, but usage is not limited to such applications.

Certain processing procedures and service conditions may cause these products to become subject to stress-corrosion cracking; ARP982 recommends practices to minimize such conditions.

Chemical components(%)

Composition | C | O | N | H | Fe | Al | V | Y |

Min | \ | \ | \ | \ | \ | 5.50 | 3.50 | \ |

Max | 0.08 | 0.20 | 0.05 | 0.0125 | 0.30 | 6.75 | 4.50 | 0.005 |

Condition

Bars

Hot finished with or without subsequent cold reduction, solution heat treated, aged, and descaled.

Wire

Cold drawn, solution heat treated, aged, and descaled.

Forgings and Flash Welded Rings

Solution heat treated, aged, and descaled.

Flash welded rings shall not be supplied unless specified or permitted on purchasers part drawing. When supplied, rings shall be manufactured in accordance with AMS 7498.

Stock for Forging or Flash Welded Rings

As ordered by the forging or flash welded ring manufacturer.

Heat Treatment

Bars, wire, forgings, and flash welded rings shall be solution heat treated by heating in a suitable atmosphere to 1750°F±25 (954°C ±14), holding at heat for 1 to 2 hours, and quenching in agitated water, and aged by heating to a temperature within the range 900 to 1150°F (482 to 621°C), holding at the selected temperature within ±15°F (±8°C) for 4 to 8 hours, and cooling in air. Pyrometry shall be in accordance with AMS 2750.

MONO Group is one of Titanium and Titanium alloy manufacturer&Supplier&Wholesaler from China,We can supply ASTM /DIN/ISO/GB/AMS stndard high quality Titanium plate,sheet,round bar,wires,tube.pipes,fittings,flange,pls contact us freely for your RFQ to info@monokj.com